Ningbo Hengkang Food Company was founded in 1996 and specializes in the production and sale of roasted nuts, offering 32 different varieties. Initially, the company relied on manual labeling, which often resulted in skewed and misaligned labels, leading to rejected products that required re-packaging.

Manual labeling also couldn’t keep up with the fast-paced production line, which extended production cycles and ultimately affected overall output.

After thoroughly understanding the client's needs, we recommended our precision round bottle labeling machine, customizing the solution to fit their production line's unique requirements. Compared to their previous manual process, our labeling machine offers the following advantages:

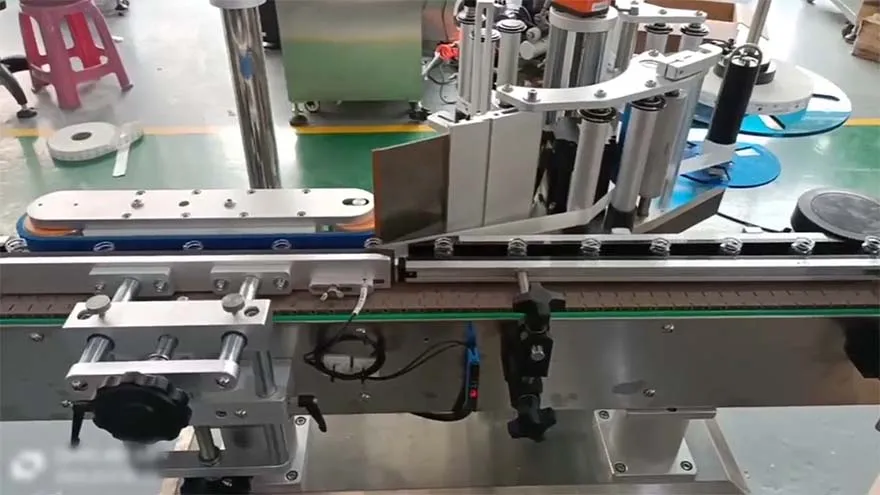

The wrap around labeling machine with wrap belt is perfect for your upright bottle labeling needs! Whether you need it as a standalone unit or part of a production line, it’s built to adapt. With its automatic bottle separation function and 24/7 operation capability, you’ll enjoy uninterrupted performance.

Three Squirrels Snack Food Company specializes in producing a wide range of snack products, including nuts, jerky, and dried fruits, with packaging available in multiple specifications. The company required a high-efficiency automated labeling solution to ensure fast and precise labeling, reduce labor costs, and maintain accurate label placement for their diverse product line.

We provided a high-speed flat surface labeling machine designed to handle various carton sizes. The machine offers precise and rapid labeling while featuring an automatic adjustment function to accommodate different packaging types. It seamlessly integrates with other production line equipment, such as filling and sealing machines, creating a streamlined operation.

With this solution, Three Squirrels achieved:

This flat surface labeling machine is designed to keep your production process smooth and accurate! With its vacuum conveyor belt, your materials stay securely in place during transport, eliminating any risk of shifting.

Alobon Cosmetics Company offers a diverse range of bottled, tube, and boxed cosmetic products, each requiring precision labeling to accommodate irregular bottle shapes and a variety of label materials. The client needed a flexible, high-precision labeling solution to meet these demands.

We provided a customized flat surface labeling machine designed for versatility and precision. This solution handles various container shapes, including bottles and tubes, and ensures seamless full-wrap label application.

The machine is equipped with automatic detection capabilities to identify label defects and misalignments, guaranteeing perfectly aligned labels on every product.

With this tailored solution, Alobon Cosmetics achieved:

This flat surface labeling machine is designed to keep your production process smooth and accurate! With its vacuum conveyor belt, your materials stay securely in place during transport, eliminating any risk of shifting.

This pharmaceutical company specializes in producing various types of medicines, where the requirements for labeling quality are far more stringent than traditional labeling needs. Packaging must strictly comply with pharmaceutical regulations, ensuring not only precise label application but also incorporating anti-counterfeiting features. The diverse sizes of medicine bottles and label specifications demand a labeling machine that can adapt to varying formats, while maintaining high-speed operations to support uninterrupted production.

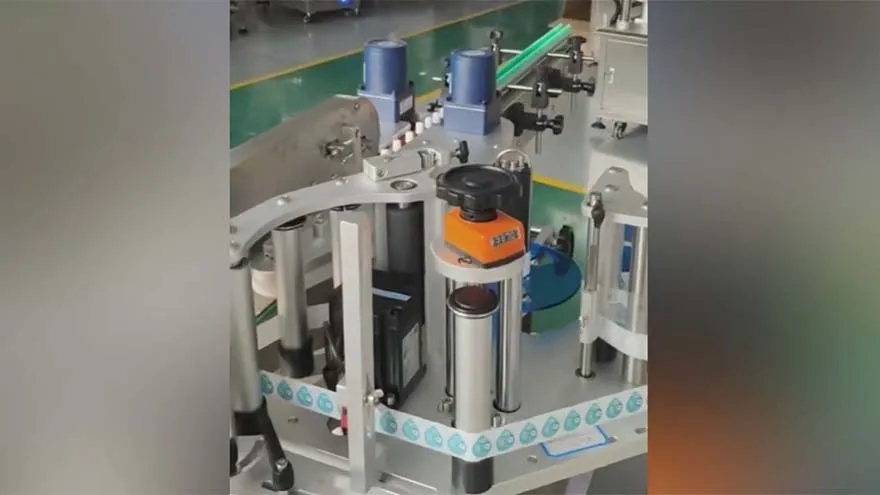

We provided a custom-designed horizontal labeling machine tailored to the client’s needs. Equipped with an advanced vision recognition system, the machine ensures accurate label placement while detecting issues such as misaligned, missing, or incorrect labels. Additionally, anti-counterfeiting features, such as QR codes and barcodes, can be integrated into the labels to enhance product security. By implementing automated labeling, the client not only improved production efficiency but also significantly reduced the risk of human error, ensuring that the pharmaceutical packaging complies with all regulatory requirements.

If you’re looking for a solution to label objects that can’t stand upright, this horizontal labeling machine is just what you need! Using a horizontal rolling method, it’s designed to handle your most challenging labeling tasks with ease.

The client specializes in producing various types of plastic bottles and molds. By implementing our labeling machine, they achieved a 30% increase in production efficiency and a 20% reduction in labor costs. Our labeling machine’s precise positioning system and fast labeling speed ensured accurate and complete label application, earning the client’s satisfaction and trust.

Designed to make your labeling process faster and more efficient, our front and back labeling machine features a dual-sided separation design; it can label both sides of your products simultaneously, reaching speeds of up to 200 bottles per minute. It’s fully adjustable to meet your specific requirements for flat surface labeling.

Contact us to see how we can help improve your production efficiency with reliable and customized labeling machines.