We are dedicated to ensuring your labeling equipment operates at peak performance and meets your production goals. Our comprehensive support services cover every stage of your journey:

Have questions? Our technical team is ready to assist. We offer expert advice to help you choose the ideal labeling machine, considering production efficiency, labeling precision, and ease of use. For unique requirements, we provide detailed consultations to explain technical specifications and how our machines can address your specific production challenges.

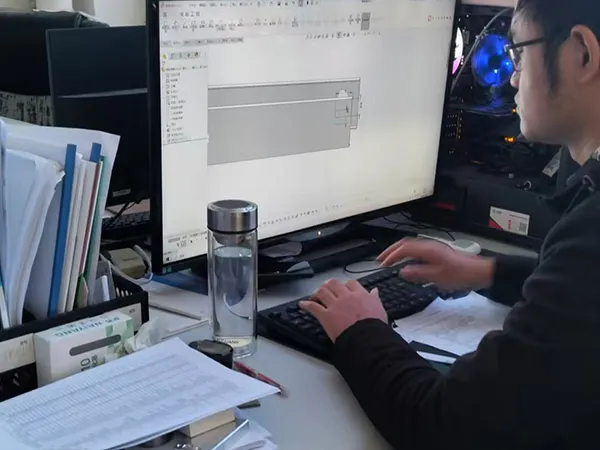

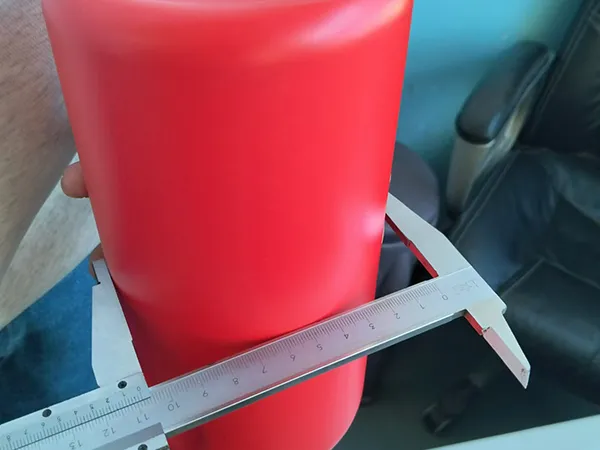

We take the time to understand your production needs, bottle types, label materials, and desired production speeds. Using this information, we develop tailored solutions that include the most suitable machine models, functional modules (like automation or detection), and configurations.

Before delivery, our engineers conduct rigorous testing to guarantee optimal performance. If you need reassurance, we can simulate your production environment and test samples on the equipment. You’ll receive detailed feedback on the results to ensure compatibility.

Our technical experts install your equipment in line with your production layout, ensuring smooth integration with existing systems. On-site testing in real production conditions allows us to fine-tune labeling precision and speed to meet your requirements.

We provide hands-on training for your team, covering equipment operation, adjusting parameters like speed and precision, performing maintenance, and adhering to safety protocols. Detailed manuals and instructional videos are available to help your staff confidently operate the machine.

To keep your equipment running smoothly, we offer regular maintenance reminders and, if necessary, on-site inspections. For machines with mechanical parts, we provide periodic lubrication and cleaning services to maintain high performance.

For equipment issues, contact us via phone, email, or video for remote troubleshooting. If the problem cannot be resolved remotely, our technicians will provide on-site support.

When your production needs evolve, we offer upgrades and retrofits to enhance your equipment. From adding automation to improving the control system, we’ll ensure your machine meets your changing demands.

We ensure the availability of essential spare parts, such as label dispensers, rollers, sensors, and servo motors. Parts can be ordered through our website, customer service hotline, or distributor network.

Contact us today to see how our comprehensive services can help you achieve efficient, reliable, and high-quality production.