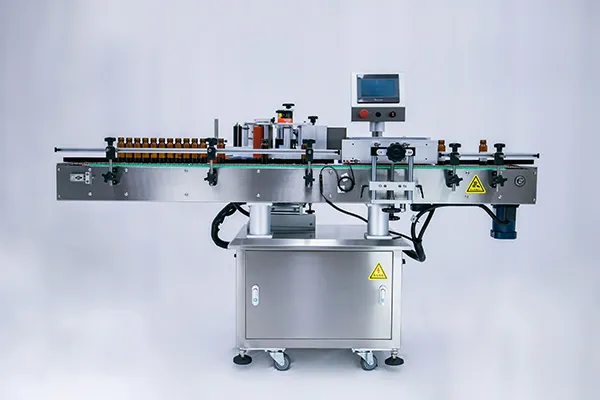

At Sanyou, we’re here to make your labeling process as smooth and efficient as possible. We specialize in designing labeling machines customized to fit your unique production needs, product specifications, and work environment.

We understand that your products and production lines may require different configurations to achieve accurate, efficient label application. That’s why we offer tailored solutions that not only boost your production efficiency but also address specific labeling challenges. Whether it’s handling special materials, ensuring precise application, or integrating with your existing production line, we’ll create a solution that works perfectly for you.

If you’re ready to take your labeling to the next level, let’s chat about how we can build the ideal machine for your business!